When building outdoor spaces that include gas-powered fire pits, fireplaces, or outdoor kitchens, appropriate gas line sizing is essential for proper performance. If you’re a contractor working on these projects, understanding how gas lines work—and their relationship to burner sizes, BTU requirements, and run length—can save you from costly mistakes.

This guide breaks down the fundamentals of gas line sizing and offers tips for getting it right the first time. And don’t forget, contractors can always take advantage of SpotixPro! It’s our exclusive trade program for pros like you to get preferred pricing and support on your next project!

What’s the Difference Between Inlet Size and Gas Line Size?

One common misconception we see is assuming that the burner inlet size (where the gas connects to the burner) is the same size as the gas line needed. Not true! Burners often have much smaller inlets than the gas line feeding them. For example, a fire pit might have a 1/2" inlet, but depending on the BTU output and distance from the gas source, you might need a 1" or larger gas line to ensure adequate supply.

This misunderstanding often leads to undersized gas lines, one of the most costly installation errors we come across. That’s why it’s crucial to calculate the required gas line size based on the BTU load and distance from the source, not just the size of the burner inlet.

What’s the Difference Between Pressure and Volume?

Think of gas pressure and volume like water flowing through a hose. You can increase pressure by squeezing the nozzle, but there’s only so much water the hose can carry at once. Similarly, increasing gas pressure (measured in inches of water column or “WC”) can help push gas through the line faster, but every system has a maximum pressure it can handle. If the line is too small or long, you won’t have enough volume to supply the burner—even if you crank up the pressure.

This is why working with an experienced gas plumber is crucial. They can do the proper BTU calculations and measure the gas pressure using a tool called a manometer to ensure the right balance between pressure and volume.

How Do You Calculate BTUs With the “Longest Run” Method?

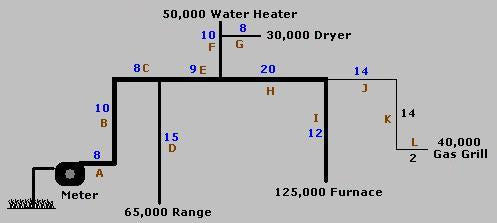

One of the most important steps in determining the right gas line size is knowing the total BTUs (British Thermal Units) required by the gas appliance. For fire pits, outdoor kitchens, or fireplaces, you typically use the length of the longest run method (fig. 1) to then determine the gas line size. This means you measure the distance from the gas meter (or tank) to the appliance, plus any additional distances created by bends or fittings, and also factor in the load of other appliances.

Gas appliances, like fire pits or outdoor grills, have specific BTU needs. The further away they are from the gas source, the larger the gas line needs to be to maintain sufficient volume and pressure. For example, a high-BTU gas fire pit with a 75-foot run will require a much larger gas line than a fire pit closer to the house.

What’s the Difference Between High vs. Low Pressure?

High-pressure systems (often used for propane and becoming more common for natural gas) allow for smaller gas lines, as higher pressure can push more gas through the pipe. However, high-pressure systems also require regulators at the appliance to reduce the pressure to a usable level. In contrast, low-pressure systems require larger gas lines to carry the same volume of gas. Most appliances need a supply pressure of 1/4 to 1/3 PSI (low pressure), while high pressure can mean 10 PSI for propane and 2 PSI for natural gas.

Simply put, high pressure can move gas further with less volume, while low pressure requires more volume to make up for the lack of pressure. Understanding which system you’re working with is critical for sizing gas lines and adding regulators to reduce pressure when needed.

Sizing Charts and Expert Help

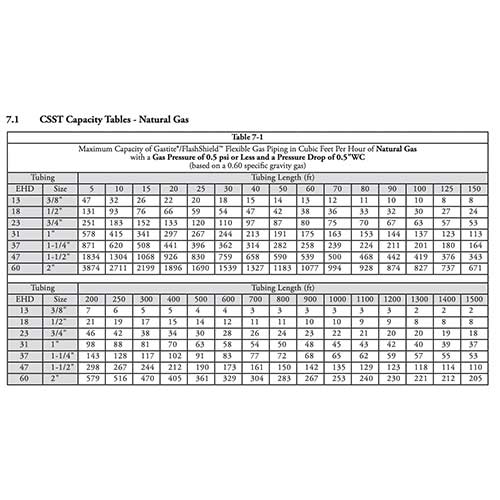

Each type of gas line—copper, steel, or flexible CSST (corrugated stainless steel tubing)—uses its own sizing chart based on BTU load, pressure, and length of run. We typically measure gas pressure in inches of water column (WC), with 1 PSI equaling 28” W.C. Make sure you’re using the correct chart for your materials and the gas system you’re working with.

Keep in mind that the gas stubbed out of a house is often insufficient for high-BTU appliances like gas fire pits; instead, a direct feed from the meter is needed. This can lead to significant problems if not planned correctly. Always consult a licensed gas plumber to ensure your gas lines are sized correctly and comply with local and national gas codes.

Avoid Costly Mistakes with SpotixPro

By sizing your gas lines correctly, you can avoid costly rework, have a safe installation, and ensure the performance of your client’s outdoor gas features. To help contractors like you succeed, our SpotixPro trade program offers access to expert advice, discounted pricing, and priority support. Join SpotixPro today to make your next outdoor gas project a breeze!

Remember: Proper gas line sizing is one of the most important aspects of any outdoor gas appliance installation. Get it right, and your clients will enjoy a beautiful, high-performing system for years to come. Get it wrong, and you might find yourself on the hook for expensive modifications. Additionally, contact our certified team of product specialists if you have any questions. We are open from 8 a.m. to 5 p.m. Monday through Friday or email us anytime.